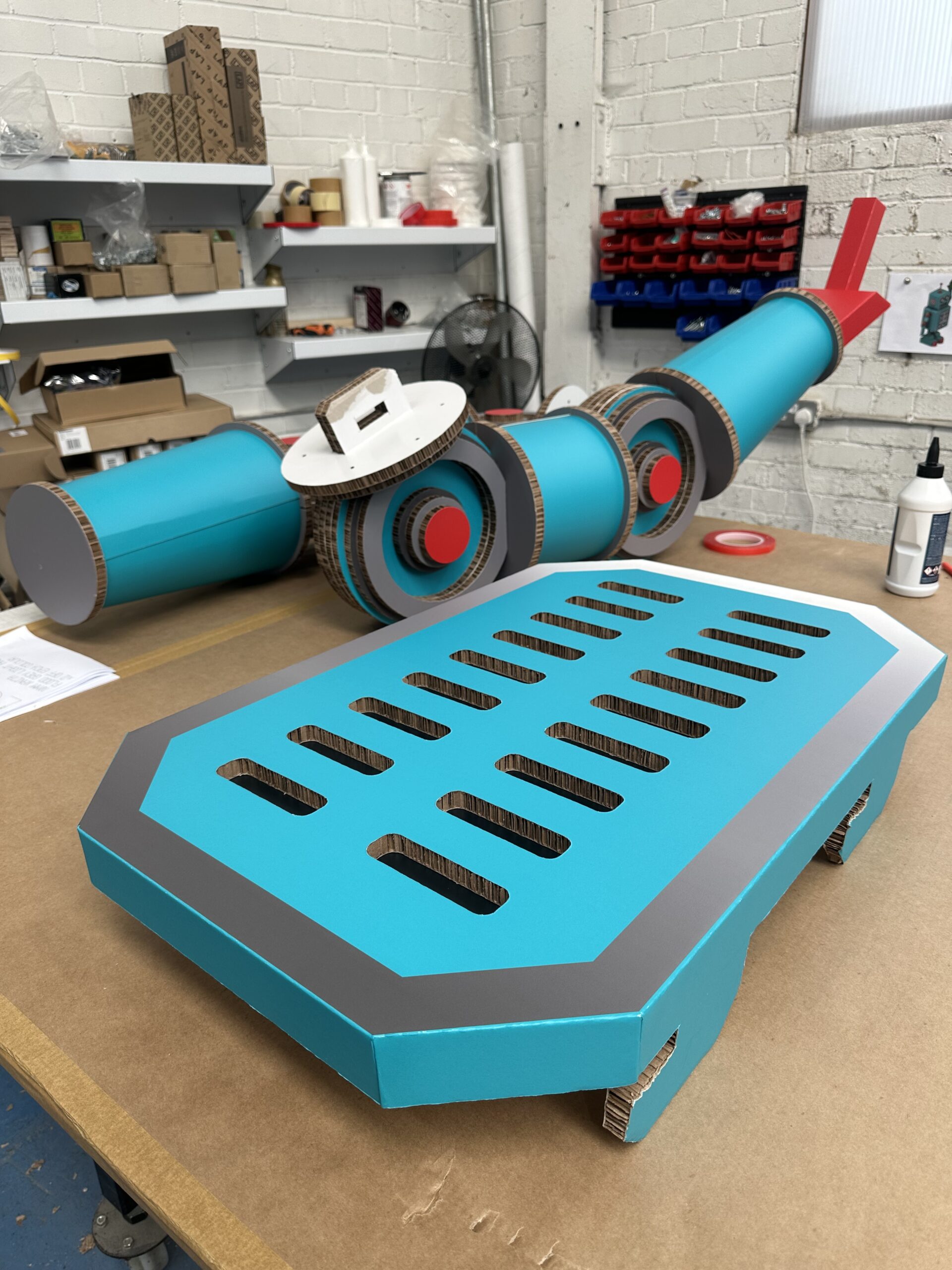

We partnered once again with our pioneering suppliers, Antalis. This time we would be supporting them with their most ambitious cardboard exhibition stand yet for VM & Display Show. Antalis wanted to push the boundaries of what is possible with cardboard engineering, showcasing the creative possibilities of Antalis’ sustainable materials. The brief was to build a GIGANTIC robot.

“After designing the initial concept for our stand, which I wanted to be centred around an oversized vintage robot and made from our Xanita Fibreboard, I turned to Imageco’s expert team to bring my vison to life. Working with a print producer who also offers a highly skilled creative studio, to design both the graphics and card engineering required made the whole process seamless and the end result was amazing – the visitors loved him!” Claire White, Design Specification Consultant at Antalis