Range of CAD Software

As an essential cog to our print and build machine, we apply a range of software that each have unique applications and advantages.

For cardboard engineering, we apply:

• KASEMAKE - A CAD application designed specifically for POS displays. It enables designers to produce 3D virtual samples and can be folded to as act as prototypes.

• Rhino 3D – This tool can create, edit, analyse, render, animate and translate surfaces and solids.

• Artios CAD – This software supports 3D structural designs by integrating seamlessly with our design and print software to quickly develop cardboard retail displays.

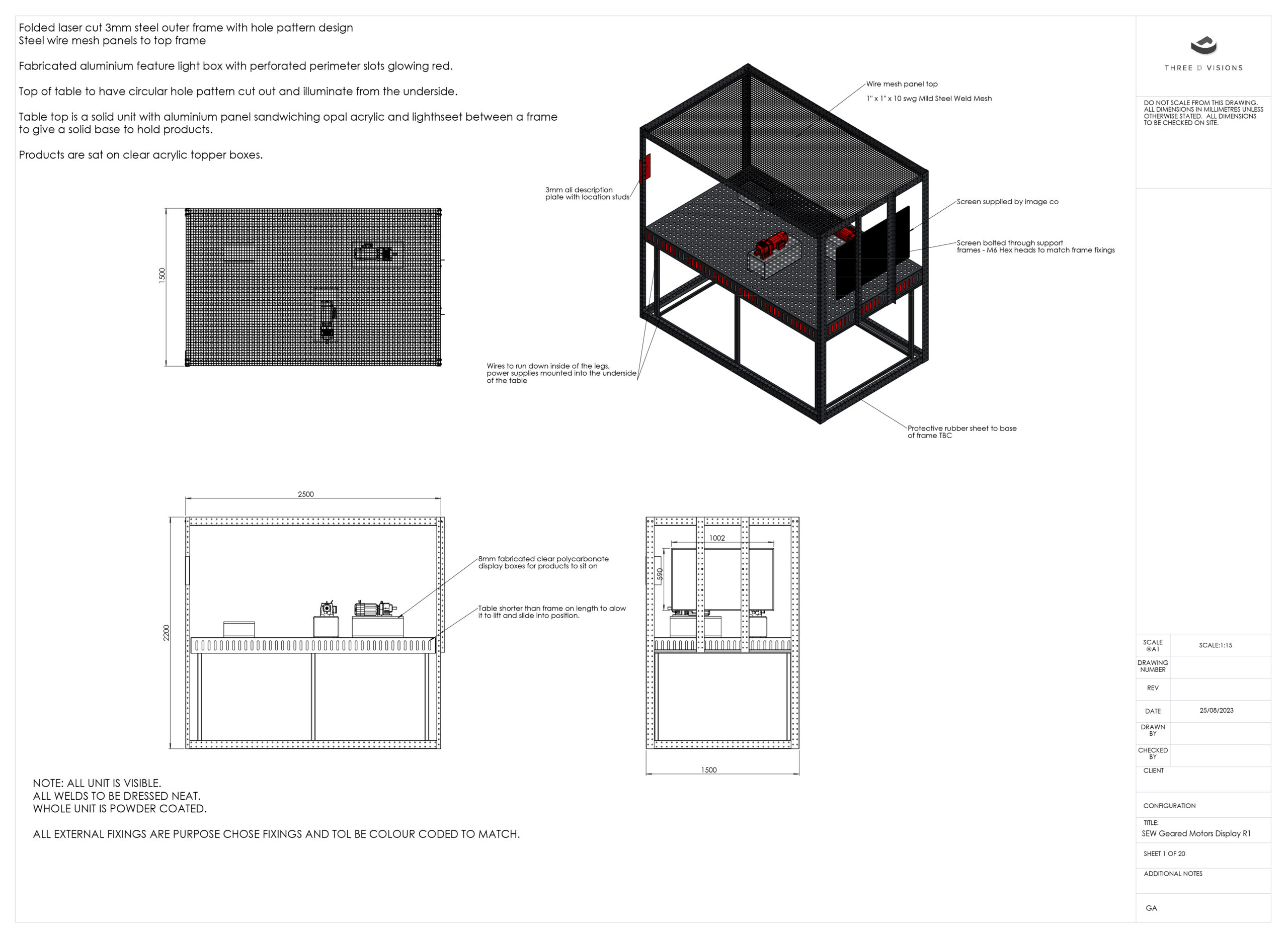

For all other materials, we utilise SOLIDWORKS® 3D CAD, which is a powerful 3D modelling tool that supports out-of-the-box ideation with an intuitive solution. It enables complex design modelling, assembling, and easily transfers component designs so they’re production-ready.